Listen to This Article

The devil, as is said, is in the details, and this is especially true when it comes to Walmart supplier requirements. Walmart is a massive, fast-moving operation dedicated to delivering a valuable service to its customers, one that relies on smooth, precise operations.

To maintain a strong working relationship (and profitability), suppliers must adhere to the systems the retail giant has put in place to ensure every delivery is smooth and efficient.

What Does it Mean to Be Compliant with Walmart?

Compliance with Walmart means following standards for packaging, labeling, shipping, which are governed by two key programs: OTIF and SQEP.

Walmart’s OTIF (On-Time In-Full) tracks delivery performance, focusing on when and how completely suppliers deliver products. The Supplier Quality Excellence Program (SQEP), on the other hand, covers things like PO accuracy, labeling compliance and how products are prepared and shipped. Together, these comprise Walmart’s supplier accountability framework.

When suppliers fail to meet these standards, Walmart will issue compliance deductions, also known as chargebacks. When the supplier is issued a deduction, the fee will be billed to suppliers as an invoice rather than the payment being withheld from payment.

Deductions can add up, especially if not monitored and recovered. Use this interactive calculator to plug in your actual figures and see exactly what recovery means for your bottom line.

To avoid these deductions and keep a smooth relationship with Walmart, suppliers should focus on being compliant in these three main areas: Packing, Labeling, and Shipping.

Packaging, Labeling, and SQEP Compliance

Before anything ships, suppliers must make sure that products are packaged and labeled according to Walmart’s standards.

Where to find Walmart’s Packaging Standards: Retail Link > Packaging & Labeling > Packaging > Scroll down to Related Help Docs > Walmart Secondary Packaging Guide

Key Packaging and Label Requirements

Item Setup

Ensure all product data (pack size, dimensions, cost) is accurate in Walmart’s systems.

Barcodes

Barcode compliance is one portion of SQEP’s Phase 2 program. Walmart measures its suppliers’ barcode compliance against their ability to receive cases based on the scanned barcode. For Walmart suppliers, there is the GS1-128 barcode, a variety of GTINs, as well as UPCs that have specific specifications like print quality, size, position, white space, etc. that need to be adhered to.

Labeling

Include scannable barcodes on each unit and case; ensure labels match item setup exactly (description, quantity, etc.); follow Walmart’s SQEP guidelines for label placement and clarity.

Pack According to Specs

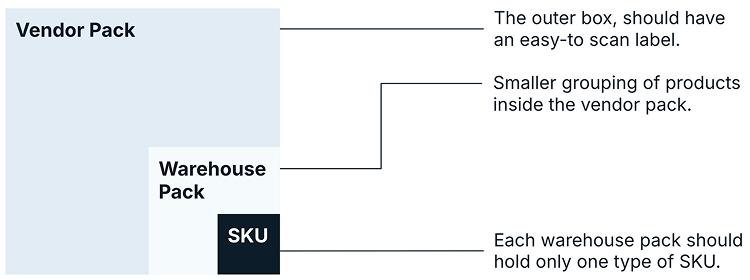

Follow Walmart’s packaging standards for vendor-pack (VNPK) and warehouse-pack (WHPK) units. The vendor pack, also known as the master pack or case pack, is the packaged quantity of merchandise sent from the supplier to the retailer’s distribution center or fulfillment center. This vendor pack contains sellable units called “eaches.” The warehouse pack is the box inside of a vendor pack that contains one or more “eaches.”

Adhering to these labeling and packaging requirements are core to Walmart’s Supplier Quality Excellence Program (SQEP) which measures how accurately and consistently suppliers prepare products for Walmart’s distribution network.

The SQEP program is broken down into four phases:

- Phase 1: PO Accuracy – Measures how accurately suppliers fulfill Walmart’s purchase orders. Revisions are allowed, but the final PO must match the items shipped exactly.

- Phase 2: Barcode & Labeling Compliance – Ensures cases can be received using scannable barcodes and that labels meet Walmart’s requirements for placement, identification, and carton markings.

- Phase 3: Packaging, Pallet & Load Compliance – Evaluates the overall quality and preparedness of shipments. This includes ensuring that packaging is durable enough to withstand handling and transit, pallets are properly labeled, secured, and meet Walmart’s quality standards, and loads are stable and correctly segregated to prevent damage or delays during transportation.

- Phase 4: Scheduling & Transportation – This phase has not yet been released but is expected to focus on delivery scheduling accuracy and transportation performance.

SQEP Best Practices

To stay compliant with Walmart SQEP and avoid costly deductions, focus on precision, documentation, and proactive process control.

- Label Accuracy: Use approved barcode formats (ITF-14 or GS1-128) with correct placement on at least two sides of each case, including correct vendor stock numbers and product dates.

- Walmart Pallet Requirements: Use Grade A pallets and secure properly; include all required shipping and item info on pallet labeling.

- Audit Regularly: Use Walmart’s SQEP dashboard to monitor and correct issues so they do not recur. Maintain records for at least 6 years.

- Train Your Team: This includes warehouse and logistics staff, ensuring they fully understand and work within SQEP standards.

- Dispute Deductions: Invalid SQEP charges can be reversed following proper procedures.

A Proactive Tool

This SQEP Audit Checklist can help prevent costly deductions.

Get your step-by-step SQEP checklist and make sure every shipment meets Walmart’s requirements.

Shipping, Delivery and OTIF Compliance

Once products are properly packaged and labeled, the next step is getting them to Walmart distribution centers. Walmart’s shipping standards are tied to the OTIF scorecard, which tracks supplier delivery performance and holds suppliers accountable for both timing and completeness of shipments.

Carrier Coordination

Walmart suppliers fall into two freight categories: Prepaid and Collect. Prepaid suppliers manage the entire purchase order lifecycle, from confirming routing to selecting carriers and arranging delivery. While this gives suppliers more control, it also increases exposure to OTIF risk as the supplier takes on all the responsibility for shipment and delivery. In contrast, Collect suppliers hand off transportation responsibilities to Walmart. However, this doesn’t mean they’re off the hook. Collect suppliers must be what Walmart calls “Collect Ready,” meaning all goods must be picked, packed, and staged correctly and on time for pickup.

Understanding the Must Arrive By Date (MABD)

Every Walmart purchase order includes a Must Arrive By Date (MABD). This is the specific date by which a shipment must be received at the Walmart distribution center. Deliveries that arrive outside the MABD window—whether early or late—are considered non-compliant and will negatively impact your OTIF score.

MABD isn’t one-size-fits-all. Depending on the department, Walmart allows different delivery windows. Here’s how those windows break down:

- MABD: Product must arrive exactly on the MABD date.

- MABD-1 Day: Product may arrive either one day before or on the MABD date.

- MABD-2 Days: Product may arrive up to two days before the MABD date.

- MABD-3 Days: Product may arrive up to three days before the MABD date.

Knowing which window applies to your category is essential for planning carrier pickups and hitting OTIF targets.

Post-Shipment Compliance

After shipping, monitor your OTIF scorecard, track delivery performance, and address late or incomplete shipments proactively.

Walmart OTIF Best Practices

Suppliers must be 98% On-Time for Collect Ready, 90% On-Time for Prepaid, and 95% In-Full to meet core OTIF targets. A 3% COGS penalty applies for non-compliant cases.

To meet those targets:

- Master the OTIF Scorecard: Stay on top of your performance in Retail Link (Walmart’s supplier portal), monitor trends, and identify causes of deductions early.

- Maintain PO Accuracy: Verify the correctness of your purchase orders, confirm routing within 24 hours, and avoid substitutions.

- Vet Your Carriers: Use 3PLs of consolidators with Walmart experience to reduce risks, ensure delivery appointments are scheduled and met precisely, and check carriers for OTIF performance history.

- Forecasting: Use Walmart’s GRS forecasting tool and supplement with your demand plans, and communicate supply constraints early to replenishment managers.

- Packaging & Labeling Discipline: In addition, as part of its SQEP audits, Walmart may audit labeling, documentation, and packaging, so maintain your records. Avoid mixed pallets; clearly label shipments to prevent DC confusion, use color-coded boxes or stickers for easy identification.

- Be Proactive: Notify Walmart of any PO changes, delays, or DC issues, and submit tickets via the Transportation Portal with any Walmart-side issues.

Preventing Costly Deductions, Chargebacks and Fines

Preventing Walmart deductions, chargebacks, and fines comes down to following the above best practices and requires a mix of proactive compliance, tight operational controls, and strategic use of automation.

“On average, what we typically will see is that less than 20% of deductions are ever actually (being) disputed when we talk to our suppliers.”

~Vanessa Cox, Strategic GTM Lead for Walmart at Carbon6

Engage with Expertise

As part of SPS Commerce, Carbon6 and SupplyPike help suppliers reclaim lost revenue, improve compliance and protect margins –without adding additional headcount. Our deduction management solution combines retailer-specific automation, real-time insights and expertise to help suppliers recover lost revenue from retailers like Walmart and Amazon –fast.

Explore Carbon6 Revenue Recovery.